Why does my Mercedes smell bad?

Dec 19, 2025

Have you recently noticed a musty smell when using the air conditioning in your Mercedes? Before rushing to spend money on compressor repairs or replacing the car condenser evaporator, check this easily overlooked "little part" - the air conditioning filter! It's like a "mask" for your AC; if it gets clogged, even the most powerful cooling system is ineffective!

Air Conditioning Filter: The Hidden "Breath Guardian"

The air conditioning filter acts as the first line of defense for the air inside your car, filtering out dust, pollen, lint, and other pollutants. However, if not replaced regularly, the filter can become completely blocked, obstructing the smooth passage of cool air and causing a sharp drop in cooling efficiency. Worse still, in damp conditions, the filter can harbor mold, leading to musty-smelling air being blown out, which not only affects comfort but may also irritate the respiratory system, posing health risks.

How often to replace it? Depends on the environment!

Normal conditions: Replace every 10,000 kilometers or every six months.

Harsh conditions: If you often drive on construction sites, dirt roads, or dusty areas, consider checking every three months; if dirty, replace immediately!

(Quick tip: A blocked filter increases the burden on the AC system, and long-term neglect may indirectly affect the efficiency of the car condenser and evaporator!)

DIY Filter Replacement in 3 Easy Steps!

Locate the filter: Open the passenger glove compartment, unfasten the two side clasps, and you will see the filter cover.

Remove the old filter: Gently pull out the filter and inspect the surface—if it's covered in black soot, leaves, or even small insects, it’s time for a change!

Install the new filter: Pay attention to the filter arrow's direction (usually pointing towards the front of the car), reinstall the cover plate, and reattach the clasps.

Immediate results after replacement! Increased airflow, fresh and odorless interior air, prevention of dust entry into the AC system, and prolongation of the lifespan of core components like the car condenser evaporator.

Why should you not overlook the filter?

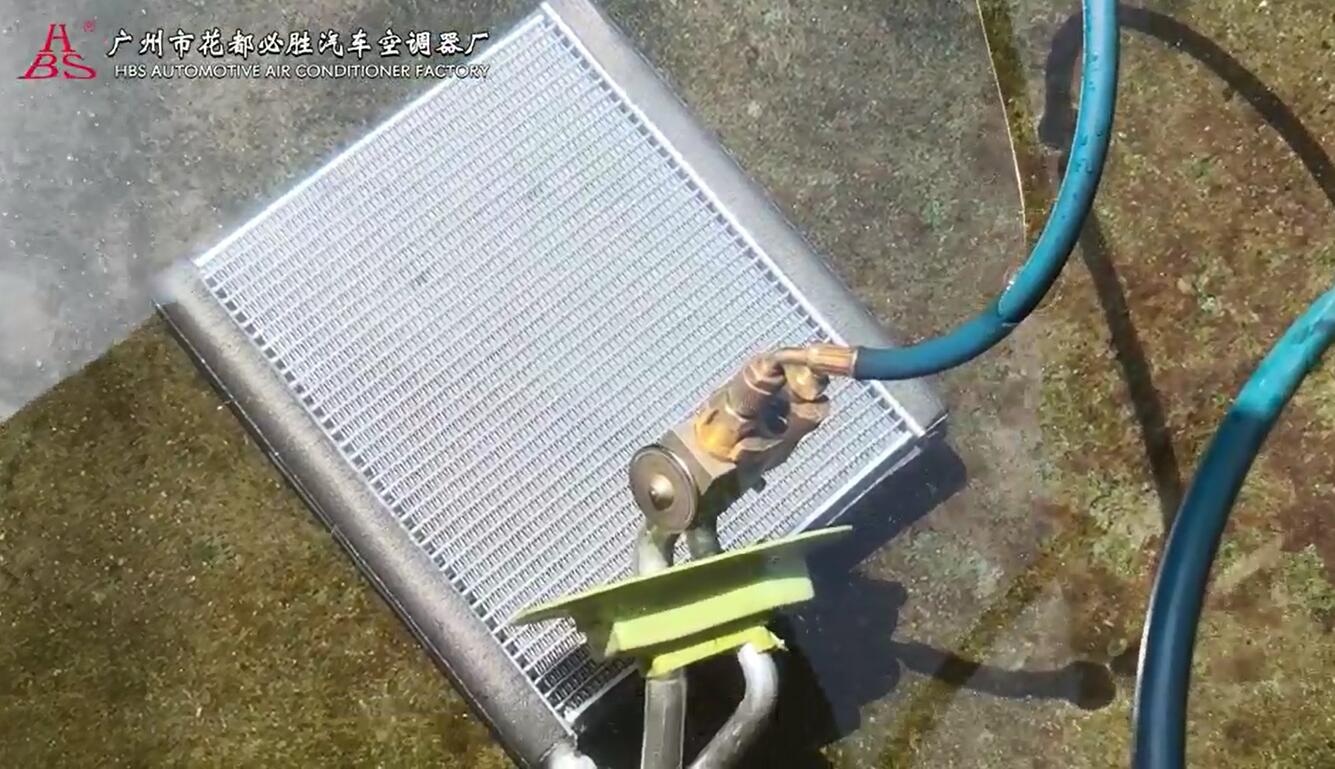

A clogged filter not only affects cooling performance but also leads to dust accumulation on the evaporator surface, reducing heat exchange efficiency and even triggering mold growth. Furthermore, if the condenser for Mercedes Benz suffers from poor heat dissipation (such as being covered with plant debris or dirt externally), it can indirectly cause a decrease in cooling effectiveness. Therefore, regularly replacing the filter and cleaning the condenser is the ultimate secret to a "full revival" of your summer air conditioning system!